A decade ago, "machine vision" meant simple sensors checking if a cap was on a bottle. They operated on rigid rules: if a pixel is black instead of white – reject.

Today, that approach is obsolete. Modern Computer Vision (CV) based on Deep Learning doesn't just "see", it "understands." It can distinguish a harmless dust particle from a critical scratch, monitor worker safety, and autonomously correct machine parameters in real-time.

For Production Managers and CTOs, the question is no longer "does it work?", but "where should we deploy it to get the highest Return on Investment (ROI)?".

In this article, we analyze concrete examples (from BMW factories to Cheetos production lines) showing how Computer Vision solves real business problems.

What is Modern Computer Vision in the Factory?

Simply put: it is the eyes of Industry 4.0. It is a system of cameras connected to Artificial Intelligence models that analyze video footage in real-time.

The key difference lies in flexibility. Old systems "got lost" when lighting changed or a product was slightly rotated. Modern neural networks learn from examples, allowing them to handle the natural variance inherent in manufacturing processes.

The main areas of application are:

Automated Visual Inspection (AVI): Detecting microscopic defects at speeds unattainable for the human eye.

HSE (Health, Safety, Environment): Monitoring whether employees are wearing helmets and vests (PPE) and ensuring they stay out of robot operating zones.

Predictive Maintenance: Thermal analysis of machinery to detect overheating components before failure occurs.

Real Case Studies: Problem -> Solution -> Result

Theory is one thing, but in business, evidence matters. Here is how industry giants are utilizing this technology.

1. BMW Group: Perfection in Every Detail

BMW is a pioneer in deploying AI on the assembly line.

The Problem: Manual inspection of paint quality and emblems was tedious for workers. Human eye fatigue after several hours of work led to errors or "false rejects."

The Solution: The AIQX (Artificial Intelligence Quality Next) system. Cameras photograph every car from multiple angles, and Deep Learning algorithms compare the image against a master standard in real-time.

The Business Result: Elimination of quality control bottlenecks and relief for employees, who can focus on repairs rather than searching for defects.

2. PepsiCo (Cheetos): The Perfect Snack via AI

This is an example of moving from "product control" to "process control."

The Problem: The shape and density of Cheetos depend on many variables (cornmeal moisture, extruder temperature). Machine operators had to constantly manually adjust settings, which was difficult during high-speed production.

The Solution: Project Bonsai (in collaboration with Microsoft). A Computer Vision system watches the conveyor belt, evaluates the texture of the snacks, and—crucially—acts as an Autonomous Agent. If the Cheetos come out too light, the AI autonomously adjusts the machine settings.

The Business Result: Drastic reduction in production waste and perfect product consistency, regardless of the operator's shift.

3. Shell: "Smart Monitoring" for Safety (HSE)

In the fuel industry, an error can cost lives. Shell leveraged CV to improve safety.

The Problem: CCTV cameras were everywhere, but security guards couldn't watch hundreds of monitors simultaneously to catch risky behaviors (e.g., lack of a helmet in a hazard zone).

The Solution: Implementation of video analytics (Azure Video Analyzer). The system automatically scans the footage for HSE violations.

The Business Result: Faster response to hazards (real-time alerts) and the ability to analyze "near-misses," allowing for preventative changes to procedures.

4. Amazon: Eliminating Damage in Logistics (Project Elyssa)

Amazon processes millions of packages a day. Manual verification of each one is impossible.

The Problem: Damaged packages were reaching customers, generating return costs and reputational damage.

The Solution: Cameras on conveyor belts scan every product. An AI model, trained on thousands of photos of crushed boxes, automatically recognizes signs of damage.

The Business Result: The system is 3x more effective than manual control. Damaged packages are automatically diverted to a side line (kick-out) before they leave the warehouse.

Tech Trends You Must Know (Tech Stack)

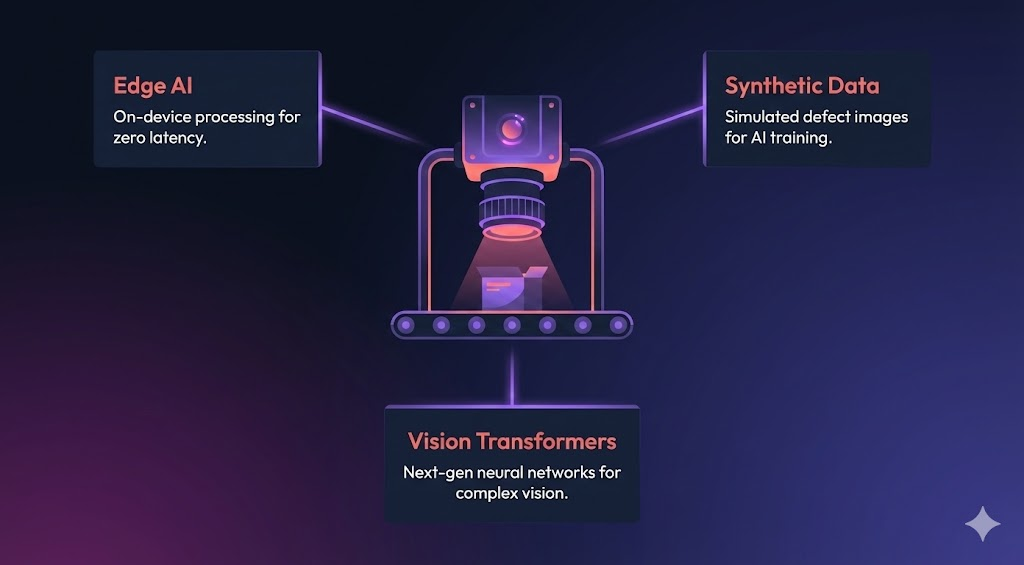

Edge AI (Processing at the Edge)

In a factory, milliseconds matter. Sending video footage from a camera to the cloud, analyzing it, and sending a signal back takes too long (latency).

The Trend: Analysis happens directly on the camera or on a small industrial computer next to the machine. The "STOP MACHINE" decision is made in a split second.

Synthetic Data

To teach AI to detect a rare defect, you need thousands of photos of that defect. But what if your production is so good that defects rarely happen?

The Trend: Companies use graphics engines (like NVIDIA Omniverse) to generate photorealistic, artificial images of defects. This allows the model to be trained even before the physical production line is launched.

Vision Transformers (ViT)

For years, Convolutional Neural Networks (CNNs) were the industry standard for analyzing images. However, for highly complex tasks—where understanding the context across the entire image is crucial, rather than just spotting local features—older CNN models sometimes hit their limits. The Trend: A modern architecture called Vision Transformers is replacing CNNs in demanding applications. ViTs process the image differently, allowing them to better "see the big picture" and understand relationships between distant parts of an object, leading to higher accuracy in complicated inspections.

Why to Invest in Computer Vision?

Computer Vision in manufacturing has stopped being a Sci-Fi experiment. It has become a cost-optimization tool.

Companies that deploy these systems gain in three ways:

Reduction in Cost of Poor Quality (COPQ): Fewer returns and less waste.

Scalability: Cameras don't get tired after 8 hours and don't need breaks.

Data: Every inspection is a database record that allows you to analyze trends and improve processes.

Is your production line ready for visual automation?

You don't have to start by revolutionizing the entire factory. We will help you identify one process (Proof of Concept) where Computer Vision will yield the fastest Return on Investment.